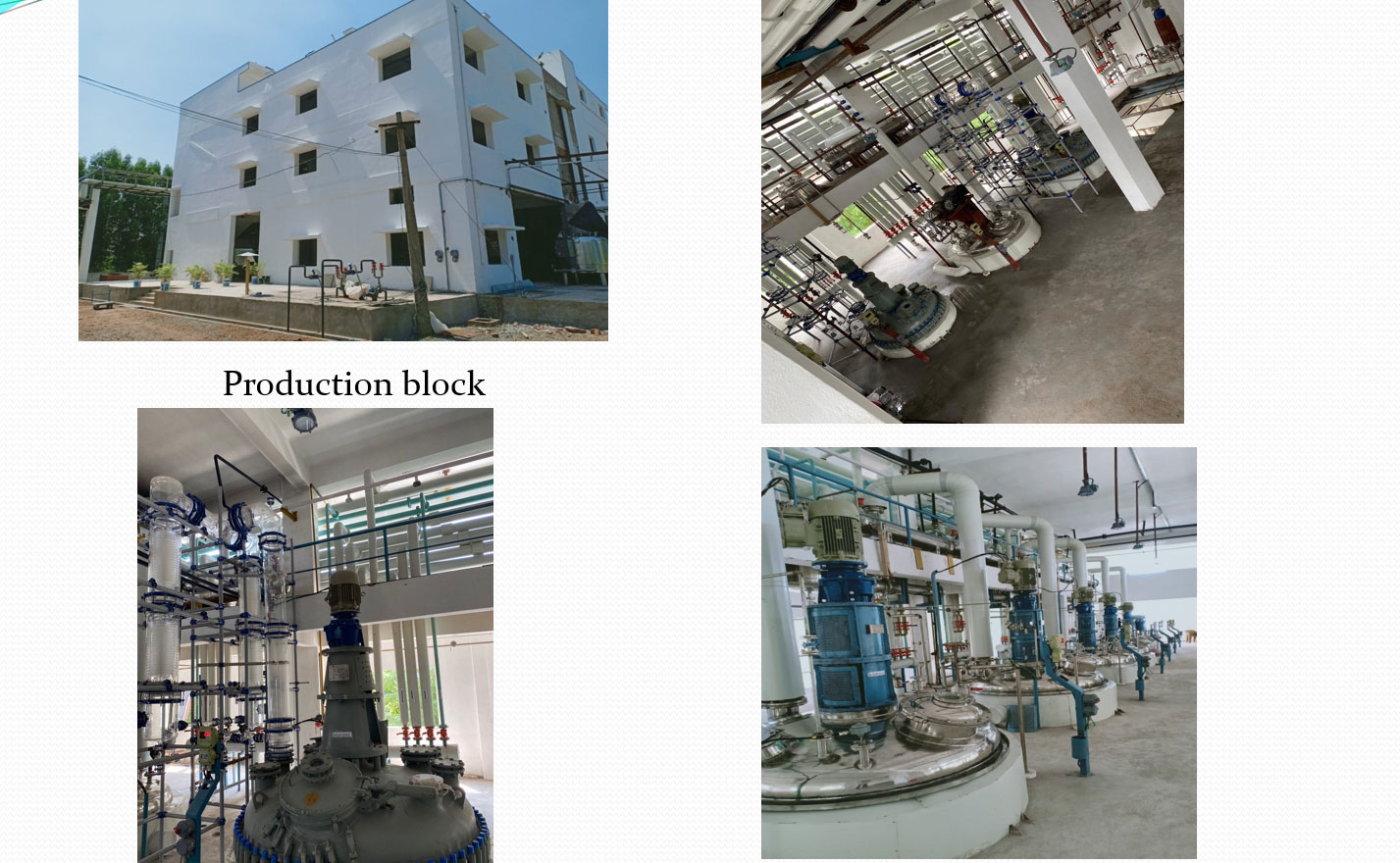

The manufacturing site covers an area of 32,051.10 square meters. The built-up RCC area spans 4,005.70 square meters, which includes a PD lab facility. Additionally, the green belt area is 11,806 square meters.

The multi-product plant has a manufacturing capacity of 51 KL, capable of producing intermediates and APIs, as well as scaling up production as needed.

Equipment details:

Major Manufacturing Equipment's

| EQUIPMENT | Qty. | Range |

| SS Reactor | 8 | 8KL, 6KL, 6KL, 5KL, 5KL, 3KL, 3KL, 2KL |

| MSGL Reactor | 4 | 2KL, 3KL, 3KL, 5KL |

| SS Centrifuge | 3 | 48” |

| Halar centrifuge | 1 | 36” |

| Agitated Nutsche Filter dryer | 1 | 3 KL |

| Leaf Filter | 3 | 100 L, 100 L, 200 L |

| Tray Dryer | 3 | 96 Trays |

| Multi mill | 1 | 50-250 Kg/hr. |

| Sifter | 1 | 30-300 Kg/hr |

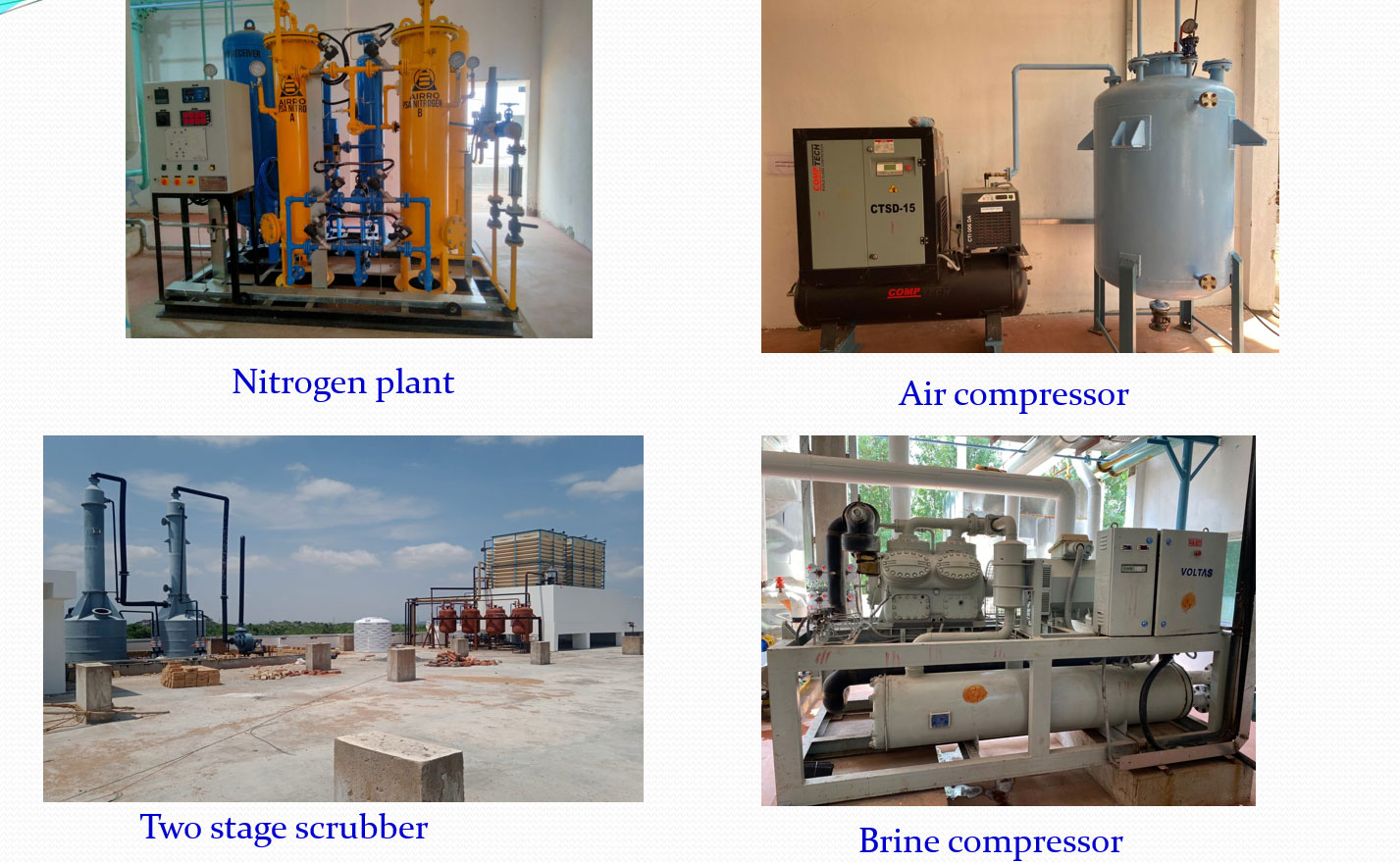

Utility Capacity

| S No | Equipment name | Capacity |

| 1 | Transformer | 950 KVA |

| 2 | Air compressor | 60 cfm |

| 3 | Nitrogen compressor | 25 Nm3/ hr |

| 4 | DG set | 500 KVA |

| 5 | Brine compressor | 40 TR (-200C) |

| 6 | Chilled water compressor | 110 TR (0 to 50C) |

| 7 | Boiler | 3 Ton |

| 8 | RO plant | 2 KL/hr |

| 9 | Softener | 4 KL/hr |

| 10 | MGF & ACF water system | 15 m3 @ 3kg/cm2 |

| 11 | Vacuum pumps | Steam jet, PP jet, Water ring |

| 12 | Cooling tower | 500 TR, 300 TR, 250 TR, 150 TR |

| 13 | MEE & ZLD system | 30 KLD |

Quality Control

| Equipment | Quantity |

| GC | 1 |

| HPLC | 1 |

| Muffel Furness | 1 |

| TDS meter | 1 |

| pH meter | 1 |

| KF Titrator | 1 |

| UV Chamber | 1 |

| Ultra sonicator | 2 |